0507691601

Info@ahren-fzco.com

AHREN PETROCHEMICALS TRADING OFFICE 2F-14, MAJID SULTAN - BUILDING AL MUTEENA, DUBAI, UAE

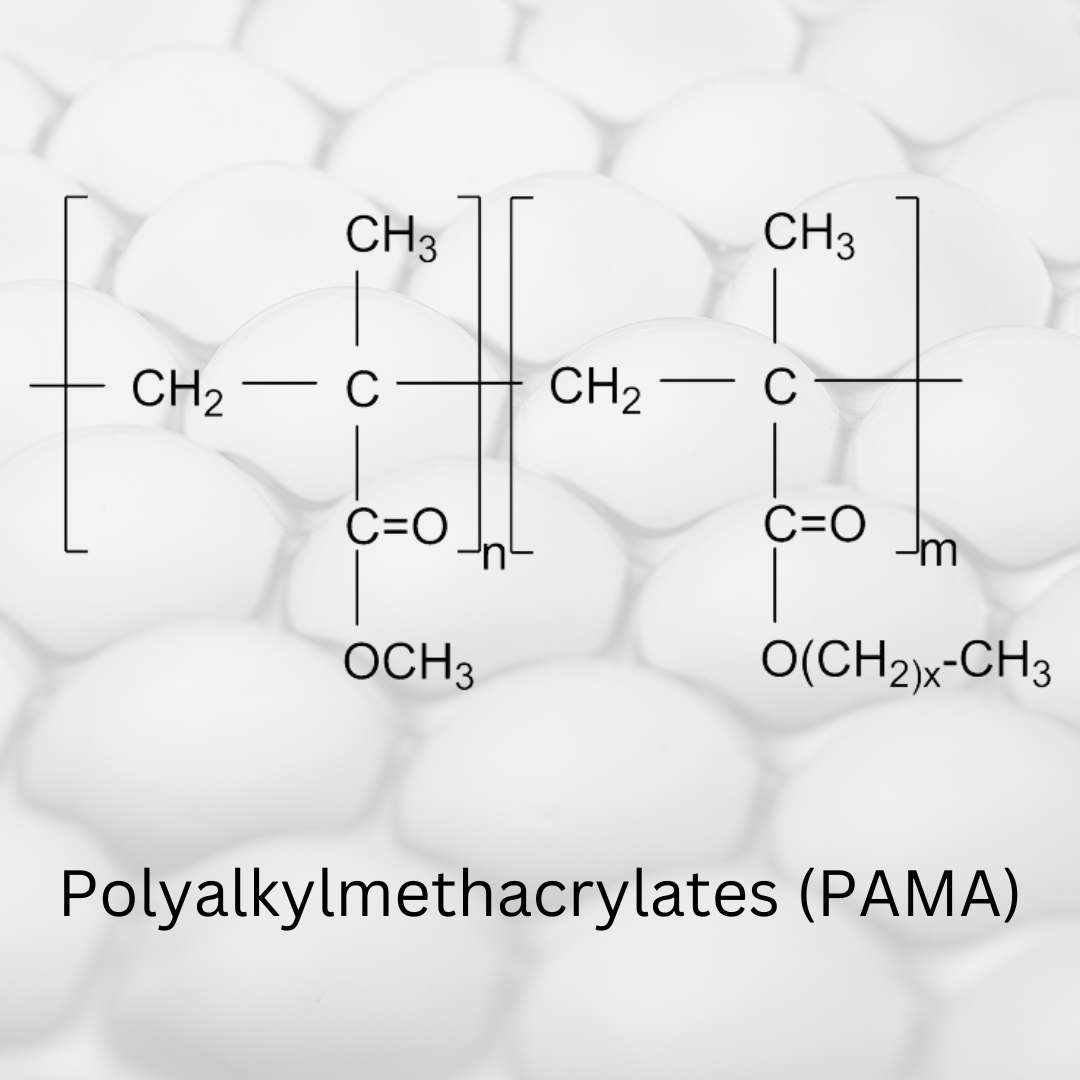

In the business world, polyalkylmethacrylates (PAMA) have been used for a long time as important ingredients in making lube oils, especially "green technology"-based ingredients. When naturally occurring vegetable-based fatty alcohols are mixed with methacrylic acid or methyl methacrylate (MMA), the monomers are formed. The versatile chemistry and easy access to a wide range of monomers, including those that don't disperse and those that do, make it possible to make polymers with the exact makeup and properties that are needed. To make PAMA polymers useful for many different tasks, the architecture of the polymers has been changed from simple (linear, branched) to more complex (block, star, comb). The comonomer compositions, molecular weights, and polydispersities have also been changed through controlled or normal free radical polymerization. Based on PAMA chemistry, viscosity index improvers (VII) and pour point depressants (PPD) for engine oils, driveline fluids, and hydraulic fluids are thought to be the most useful of all the chemicals that are already out there. Friction reducers, polymeric emulsions, and synthetic oils based on low molecular weight PAMA have been made or are already on the market. PAMA polymers are great at working at low temperatures, which means they can be used to improve the flow of biofuels when they are not being used as lubricants.